How to create a financial forecast for a steel manufacturer?

Creating a financial forecast for your steel manufacturing business, and ensuring it stays up to date, is the only way to maintain visibility on future cash flows.

This might sound complex, but with the right guidance and tools, creating an accurate financial forecast for your steel manufacturing business is not that hard.

In this guide, we'll cover everything from the main goal of a financial projection, the data you need as input, to the tables that compose it, and the tools that can help you build a forecast efficiently.

Without further ado, let us begin!

Why create and maintain a financial forecast for a steel manufacturing business?

In order to prosper, your business needs to have visibility on what lies ahead and the right financial resources to grow. This is where having a financial forecast for your steel manufacturing business becomes handy.

Creating a steel manufacturing business financial forecast forces you to take stock of where your business stands and where you want it to go.

Once you have clarity on the destination, you will need to draw up a plan to get there and assess what it means in terms of future profitability and cash flows for your steel manufacturing business.

Having this clear plan in place will give you the confidence needed to move forward with your business’s development.

Having an up-to-date financial forecast for a steel manufacturing business is also useful if your trading environment worsens, as the forecast enables you to adjust to your new market conditions and anticipate any potential cash shortfall.

Finally, your steel manufacturing business's financial projections will also help you secure financing, as banks and investors alike will want to see accurate projections before agreeing to finance your business.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast to assess the potential profitability of your projects, and write a business plan that’ll wow investors.

What information is used as input to build a steel manufacturing business financial forecast?

A steel manufacturing business's financial forecast is only as good as the inputs used to build it.

If you are creating (or updating) the forecast of an existing steel manufacturing business, then you mostly need your accounting information, key historical operating non-financial data, and your team’s input on what to expect for the coming years.

If you are building financial projections for a steel manufacturing business startup, you will need to have done your research and have a clear picture of your competitive environment and go-to-market strategy so that you can forecast sales accurately.

For a new venture, you will also need a precise list of the resources needed to keep the steel manufacturing business running on a day-to-day basis and a list of the equipment and expenditures required to start the business (more on that later).

Let's now take a closer look at the elements that make up your steel manufacturing business's financial forecast.

The sales forecast for a steel manufacturing business

From experience, it usually makes sense to start your steel manufacturing business's financial projection with the revenues forecast.

The inputs used to forecast your sales will include the historical trading data of your steel manufacturing business (which can be used as a starting point for existing businesses) and the data collected in your market research (which both new ventures and existing businesses need to project their sales forward).

Your steel manufacturing business's sales forecast can be broken down into two key estimates:

- The average price

- The number of monthly transactions

To assess these variables accurately, you will need to consider the following factors:

- Changes in raw material prices: You may experience fluctuations in the average price of your steel products due to changes in the cost of raw materials such as iron ore, coal, and scrap metal. Any increase in the cost of these materials will lead to an increase in your average price, while a decrease will result in a lower average price.

- Demand from key industries: The demand for steel products is heavily influenced by the performance of key industries such as construction, automotive, and energy. Changes in the demand from these industries can impact the number of monthly transactions for your business. For example, a boom in the construction industry may lead to an increase in demand for your steel products, resulting in higher transaction numbers.

- Competition from foreign markets: Your business may face competition from foreign steel manufacturers who offer lower prices. This can put downward pressure on your average price and affect your monthly transactions as customers may choose to purchase from these competitors instead.

- Technological advancements: Advancements in technology can impact the steel manufacturing industry in various ways. For instance, the development of new production techniques or machinery may lead to a decrease in production costs, allowing you to offer lower prices and potentially increase your transaction numbers.

- Government policies and regulations: Changes in government policies and regulations, such as tariffs and trade agreements, can affect the cost of importing and exporting steel products. This can have an impact on your average price and the number of monthly transactions as it may become more expensive or difficult to sell your products in certain markets.

Once you have a sales forecast in place, the next step will be to work on your overhead budget. Let’s have a look at that now.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast to assess the potential profitability of your projects, and write a business plan that’ll wow investors.

The operating expenses for a steel manufacturing business

The next step is to estimate the costs you’ll have to incur to operate your steel manufacturing business.

These will vary based on where your business is located, and its overall size (level of sales, personnel, etc.).

But your steel manufacturing business's operating expenses should normally include the following items:

- Raw Materials: As a steel manufacturer, you will need to purchase raw materials such as iron ore, coal, and limestone to produce steel.

- Labor Costs: Your biggest expense will be paying your employees, including factory workers, engineers, and administrative staff.

- Electricity and Utilities: Running a steel manufacturing plant requires a significant amount of electricity and other utilities, such as water and gas.

- Maintenance and Repairs: To keep your equipment and machinery in good working condition, you will need to budget for regular maintenance and repairs.

- Transportation and Logistics: Once your steel is produced, you will need to transport it to customers or to other facilities for further processing.

- Insurance: Protecting your business from potential risks and liabilities is crucial, so you will need to budget for insurance costs.

- Accounting and Bookkeeping: Keeping accurate financial records and filing taxes are important for any business, including a steel manufacturing company.

- Software Licenses: You may need to purchase software for inventory management, accounting, or other business operations.

- Marketing and Advertising: To attract new customers and maintain relationships with existing ones, you may need to invest in marketing and advertising efforts.

- Training and Development: As technology and industry standards change, it is important to train your employees and keep their skills up-to-date.

- Rent or Lease: If you do not own the facility where you manufacture steel, you will need to budget for rent or lease payments.

- Banking Fees: Maintaining a business bank account and processing transactions may come with fees, so be sure to include these in your budget.

- Taxes and Licenses: Your steel manufacturing business may be subject to various taxes and licensing fees, so be sure to budget for these expenses.

- Employee Benefits: In addition to wages, you may need to provide benefits such as health insurance, retirement plans, and paid time off for your employees.

- Safety Equipment and Training: To ensure the safety of your employees, you may need to provide them with protective equipment and training.

This list is not exhaustive by any means, and will need to be tailored to your steel manufacturing business's specific circumstances.

What investments are needed to start or grow a steel manufacturing business?

Creating and expanding a steel manufacturing business also requires investments which you need to factor into your financial forecast.

Capital expenditures and initial working capital items for a steel manufacturing business could include elements such as:

- Machinery and Equipment: This includes essential equipment such as blast furnaces, rolling mills, and other machinery used in the steel production process.

- Infrastructure: This includes the construction and maintenance of facilities, such as warehouses, storage yards, and transportation systems, that are necessary for the steel manufacturing business to operate.

- Technology and Software: In today's competitive market, investing in advanced technology and software is crucial for a steel manufacturing business to stay efficient and productive. This can include computer-aided design (CAD) software, inventory management systems, and other tech tools.

- Land and Buildings: A steel manufacturing business requires a significant amount of land and buildings to house its operations. This can include purchasing or leasing land, constructing new buildings, or renovating existing ones.

- Vehicles and Transportation: As a steel manufacturing business, you will likely need to transport raw materials and finished products to and from your facilities. This may require investing in trucks, trailers, and other vehicles to ensure efficient and timely transportation.

Again, this list is not exhaustive and will need to be adjusted according to the circumstances of your steel manufacturing business.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast to assess the potential profitability of your projects, and write a business plan that’ll wow investors.

The financing plan of your steel manufacturing business

The next step in the creation of your financial forecast for your steel manufacturing business is to think about how you might finance your business.

You will have to assess how much capital will come from shareholders (equity) and how much can be secured through banks.

Bank loans will have to be modelled so that you can separate the interest expenses from the repayments of principal, and include all this data in your forecast.

Issuing share capital and obtaining a bank loan are two of the most common ways that entrepreneurs finance their businesses.

What tables compose the financial plan for a steel manufacturing business?

Now let's have a look at the main output tables of your steel manufacturing business's financial forecast.

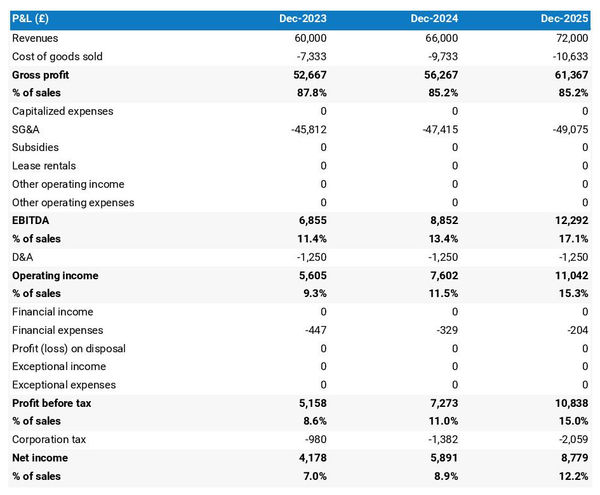

The forecasted profit & loss statement

The profit & loss forecast gives you a clear picture of your business’ expected growth over the first three to five years, and whether it’s likely to be profitable or not.

A healthy steel manufacturing business's P&L statement should show:

- Sales growing at (minimum) or above (better) inflation

- Stable (minimum) or expanding (better) profit margins

- A healthy level of net profitability

This will of course depend on the stage of your business: numbers for an established steel manufacturing business will look different than for a startup.

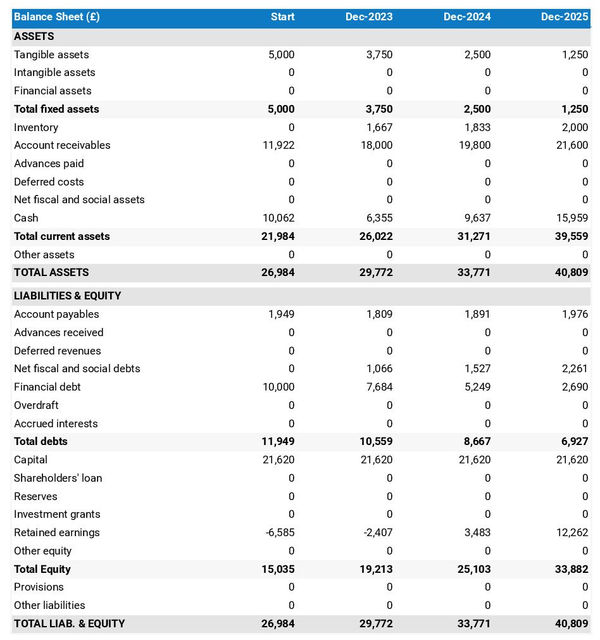

The projected balance sheet

Your steel manufacturing business's forecasted balance sheet enables you to assess your financial structure and working capital requirements.

It is composed of three types of elements: assets, liabilities and equity:

- Assets: represent what the business owns and uses to produce cash flows. It includes resources such as cash, equipment, and accounts receivable (money owed by clients).

- Liabilities: represent funds advanced to the business by lenders and other creditors. It includes items such as accounts payable (money owed to suppliers), taxes due and loans.

- Equity: is the combination of what has been invested by the business owners and the cumulative profits and losses generated by the business to date (which are called retained earnings). Equity is a proxy for the value of the owner's stake in the business.

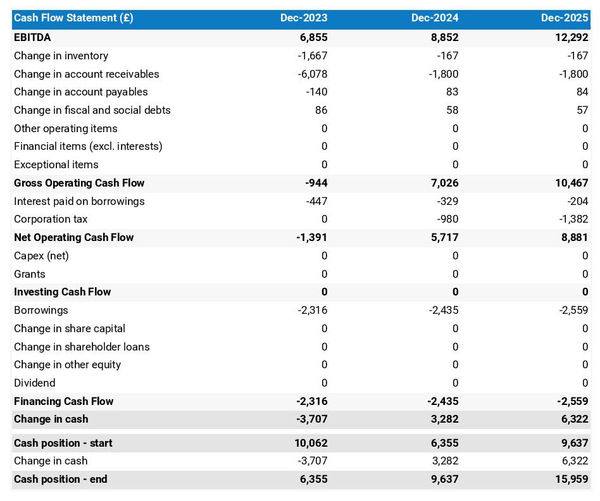

The cash flow projection

The cash flow forecast of your steel manufacturing business will show how much cash the business is expected to generate or consume over the next three to five years.

There are multiple ways of presenting a cash flow forecast but from experience, it is better to organise it by nature in order to clearly show these elements:

- Operating cash flow: how much cash is generated by the steel manufacturing business's operations

- Investing cash flow: what is the business investing to expand or maintain its equipment

- Financing cash flow: is the business raising additional funds or repaying financiers (debt repayment, dividends)

Your cash flow forecast is the most important element of your overall financial projection and that’s where you should focus your attention to ensure that your steel manufacturing business is adequately funded.

Note: if you are preparing a financial forecast in order to try to secure funding, you will need to include both a yearly and monthly cash flow forecast in your steel manufacturing business's financial plan.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast to assess the potential profitability of your projects, and write a business plan that’ll wow investors.

Which tool should you use to create your steel manufacturing business's financial projections?

Building a steel manufacturing business financial forecast is not difficult provided that you use the right tool for the job. Let’s see what options are available below.

Using online financial forecasting software to build your steel manufacturing business's projections

The modern and easiest way is to use an online financial forecasting tool such as the one we offer at The Business Plan Shop.

There are several advantages to using specialised software:

- You can easily create your financial forecast by letting the software take care of the financial calculations for you without errors

- You have access to complete financial forecast templates

- You get a complete financial forecast ready to be sent to your bank or investors

- You can easily track your actual financial performance against your financial forecast, and recalibrate your forecast as the year goes by

- You can create scenarios to stress test your forecast's main assumptions

- You can easily update your forecast as time goes by to maintain visibility on future cash flows

- You have a friendly support team on standby to assist you when you are stuck

- It’s cost-efficient and much cheaper than using an accountant or consultant (see below)

If you are interested in this type of solution, you can try our projection software for free by signing up here.

Calling in a financial consultant or chartered accountant

Outsourcing the creation of your steel manufacturing business financial forecast is another possible solution.

This will cost more than using software as you can expect as your price will have to cover the accountant’s time, software cost, and profit margin.

Price can vary greatly based on the complexity of your business. For a small business, from experience, a simple three-year financial forecast (including a balance sheet, income statement, and cash flow statement) will start at around £700 or $1,000.

Bear in mind that this is for forecasts produced at a single point in time, updating or tracking your forecast against actuals will cost extra.

If you decide to outsource your forecasting:

- Make sure the professional has direct experience in your industry and is able to challenge your assumptions constructively.

- Steer away from consultants using sectorial ratios to build their client’s financial forecasts (these projections are worthless for a small business).

Why not use a spreadsheet such as Excel or Google Sheets to build your steel manufacturing business's financial forecast?

Creating an accurate and error-free steel manufacturing business financial forecast on Excel (or any spreadsheet) is very technical and requires both a strong grasp of accounting principles and solid skills in financial modelling.

Most entrepreneurs lack the expertise required to create an accurate financial forecast using spreadsheet software like Excel or Google Sheets. As a result, it is unlikely anyone will trust your numbers.

The second reason is that it is inefficient. Building forecasts on spreadsheets was the only option in the 1990s and early 2000s, nowadays technology has advanced and software can do it much faster and much more accurately.

This is why professional forecasters all use software. With the rise of AI, software is also becoming smarter at helping us detect mistakes in our forecasts and helping us analyse the numbers to make better decisions.

Finally, like everything with spreadsheets, tracking actuals vs. forecasts and updating your forecast as the year progresses is manual, tedious, error-prone, and time-consuming. Whereas financial forecasting software like The Business Plan Shop is built for this.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast to assess the potential profitability of your projects, and write a business plan that’ll wow investors.

Use our financial projection templates for inspiration

The Business Plan Shop has dozens of financial forecasting templates available.

Our examples contain both the financial forecast, and a written business plan which presents, in detail, the company, the team, the strategy, and the medium-term objectives.

Whether you are just starting out or already have your own steel manufacturing business, looking at our template is always a good way to get ideas on how to model financial items and what to write when creating a business plan to secure funding.

Takeaways

- Having a financial forecast enables you to visualise the expected growth, profitability, and cash generation for your business over the next three to five years.

- Tracking actuals vs. forecast and keeping your financial projections up-to-date is the only way to get a view on what your steel manufacturing business future cash flows may look like.

- Using financial forecasting software is the mordern and easy way to create and maintain your forecasts.

This is the end of our guide on how to build the financial forecast for a steel manufacturing business, we hope you found it useful. Don't hesitate to contact us if you want to share your feedback or have any questions.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast to assess the potential profitability of your projects, and write a business plan that’ll wow investors.

Also on The Business Plan Shop

- Example of financial forecast

- How to project revenues for a business?

- Example of financial forecast for business idea

Know someone who owns or is thinking of starting a steel manufacturing business? Share our forecasting guide with them!