How to open a rubber and plastic maker?

Are you keen to open a rubber and plastic manufacturing business but don't know where to begin? Then you're in luck because this guide will lead you through all the steps required to check if your business idea can be profitable and, if so, turn it into a reality.

Our guide is for prospective entrepreneurs who are thinking about starting a rubber and plastic manufacturing business no matter how far they are in their journey - whether you’re just thinking about it or in the middle of market research this guide will be useful to you.

Think of this as your blueprint: we cover everything you need to know about opening a rubber and plastic manufacturing business and what key decisions you’ll need to make along the way.

Ready? Let’s get started!

Understanding how a rubber and plastic manufacturing business works

The very first step when exploring a business idea such as starting a rubber and plastic manufacturing business is to make sure you understand how the business operates and makes money (which is what we call the business model).

This will not only give you an initial idea of how profitable the business can be, but it will also enable you to make sure that this is the right business idea for you, given your skills, start-up capital and family or personal lifestyle, in particular.

The best ways to get to grips with the rubber and plastic manufacturing business's business model are to:

- Talk to rubber and plastic manufacturing business owners with experience

- Work a few months in a rubber and plastic manufacturing business already in operation

- Take a training course

Talk to rubber and plastic manufacturing business owners with experience

Experienced rubber and plastic manufacturing business owners have valuable insights and can provide practical advice based on their firsthand experiences.

They've likely encountered and overcome challenges that a newcomer might not anticipate. Learning from other’s mistakes can save you both time and money and potentially increase your venture’s chances of succeeding.

Work a few months in a rubber and plastic manufacturing business already in operation

Obtaining work experience in the industry can be a crucial factor in confirming whether you truly want to start a rubber and plastic manufacturing business, as it provides insight into the day-to-day activities.

For instance, if the working hours are longer than expected or if other business requirements don't align with your personal lifestyle or preferences, you might reconsider your entrepreneurial goals.

Even if you've decided that this business idea is a good fit for you, gaining work experience will still be valuable. It helps you better understand your target market and customer needs, which is likely to be beneficial when launching your own rubber and plastic manufacturing business.

Take a training course

Obtaining training within your chosen industry is another way to get a feel for how a rubber and plastic manufacturing business works before deciding to pursue a new venture.

Whatever approach you choose to familiarise yourself with the business, before going any further with your plans to open a rubber and plastic manufacturing business, make sure you understand:

- What skills are required to run the business (compare this with your own skills)

- What a typical week in the business is like (compare this with your personal or family life)

- What is the potential turnover of a rubber and plastic manufacturing business and the long-term growth prospects (compare this with your level of ambition)

- Your options once you decide to sell the business or retire (it's never too early to consider your exit)

Can your business idea be profitable?

Just enter your data and let The Business Plan Shop crunch the numbers. We will tell if your business idea can generate profits and cash flows, and how much you need to get started.

Assemble your rubber and plastic manufacturing business's founding team

The next step to start your rubber and plastic manufacturing business is to think about the ideal founding team, or to go in alone (which is always an option).

Setting up a business with several partners is a way of reducing the (high) risk of launching a rubber and plastic manufacturing business since it allows the financial risk of the project to be shared between the co-founders.

This also allows the company to benefit from a greater diversity of profiles in the management team and to spread the burden of decision-making over several shoulders.

But, running a business with multiple co-founders brings its own challenges. Disagreements between co-founders are quite common, and these can pose risks to the business. That's why it's crucial to consider all aspects before starting your business.

To make an informed decision, we suggest asking yourself these questions:

- How many co-founders would increase the project's chances of success?

- Do you and your potential partners share the same aspirations for the project?

- What is your plan B in case of failure?

Let's examine each of these questions in detail.

How many co-founders would increase the project's chances of success?

The answer to this question will depend on a number of factors, including:

- Your savings compared with the amount of initial capital needed to launch the rubber and plastic manufacturing business

- The skills you have compared with those needed to make a success of such a project

- How you want key decisions to be taken in the business (an odd number of partners or a majority partner is generally recommended to avoid deadlock)

Put simply, your partners contribute money and/or skills, and increasing the number of partners is often a good idea when one of these resources is in short supply.

Do you and your potential partners share the same aspirations for the project?

One of the key questions when selecting your potential partners will be their expectations. Do you want to create a small or large business? What are your ambitions for the next 10 or 15 years?

It's better to agree from the outset on what you want to create to avoid disagreements, and to check that you stay on the same wavelength as the project progresses to avoid frustration.

What is your plan B in case of failure?

Of course, we wish you every success, but it's wise to have a plan B when setting up a business.

How you handle the possibility of things not working out can depend a lot on the kind of relationship you have with your co-founders (like being a close friend, spouse, former colleague, etc.) and each person's individual situation.

Take, for instance, launching a business with your spouse. It may seem like a great plan, but if the business doesn't succeed, you could find yourself losing the entire household income at once, and that could be quite a nerve-wracking situation.

Similarly, starting a business partnership with a friend has its challenges. If the business doesn't work out or if tough decisions need to be made, it could strain the friendship.

It's essential to carefully evaluate your options before starting up to ensure you're well-prepared for any potential outcomes.

Is there room for another rubber and plastic manufacturing business on the market?

The next step in starting a rubber and plastic manufacturing business is to undertake market research. Now, let's delve into what this entails.

The objectives of market research

The goal here is straightforward: evaluate the demand for your business and determine if there's an opportunity to be seized.

One of the key points of your market analysis will be to ensure that the market is not saturated by competing offers.

The market research to open your rubber and plastic manufacturing business will also help you to define a concept and market positioning likely to appeal to your target clientele.

Finally, your analysis will provide you with the data you need to assess the revenue potential of your future business.

Let's take a look at how to carry out your market research.

Evaluating key trends in the sector

Market research for a rubber and plastic manufacturing business usually begins with an analysis of the sector in order to develop a solid understanding of its key players, and recent trends.

Assessing the demand

After the sector analysis comes demand analysis. Demand for a rubber and plastic manufacturing business refers to customers likely to consume the products and services offered by your company or its competitors.

Looking at the demand will enable you to gain insights into the desires and needs expressed by your future customers and their observed purchasing habits.

To be relevant, your demand analysis must be targeted to the geographic area(s) served by your company.

Your demand analysis should highlight the following points:

- Who buys the type of products and services you sell?

- How many potential customers are there in the geographical area(s) targeted by your company?

- What are their needs and expectations?

- What are their purchasing habits?

- How much do they spend on average?

- What are the main customer segments and their characteristics?

- How to communicate and promote the company's offer to reach each segment?

Analyzing demand helps pinpoint customer segments your rubber and plastic manufacturing business could target and determines the products or services that will meet their expectations.

Assessing the supply

Once you have a clear vision of who your potential customers are and what they want, the next step is to look at your competitors.

Amongst other things, you’ll need to ask yourself:

- What brands are competing directly/indirectly against your rubber and plastic manufacturing business?

- How many competitors are there in the market?

- Where are they located in relation to your company's location?

- What will be the balance of power between you and your competitors?

- What types of services and products do they offer? At what price?

- Are they targeting the same customers as you?

- How do they promote themselves?

- Which concepts seem to appeal most to customers?

- Which competitors seem to be doing best?

The aim of your competitive analysis will be to identify who is likely to overshadow you, and to find a way to differentiate yourself (more on this see below).

Regulations

Market research is also an opportunity to look at the regulations and conditions required to do business.

Ask yourself the following questions:

- Do you need a special degree to open a rubber and plastic manufacturing business?

- Are there necessary licences or permits?

- What are the main laws applicable to your future business?

At this stage, your analysis of the regulations should be carried out at a high level, to familiarize yourself with any rules and procedures, and above all to ensure that you meet the necessary conditions for carrying out the activity before going any further.

You will have the opportunity to come back to the regulation afterwards with your lawyer when your project is at a more advanced stage.

Take stock of the lessons learned from your market analysis

Market research should give you a definitive idea of your business idea's chances of commercial success.

Ideally, the conclusion is that there is a market opportunity because one or more customer segments are currently underserved by the competition.

On the other hand, the conclusion may be that the market is already taken. In this case, don't panic: the first piece of good news is that you're not going to spend several years working hard on a project that has no chance of succeeding. The second is that there's no shortage of ideas out there: at The Business Plan Shop, we've identified over 1,300 business start-up ideas, so you're bound to find something that will work.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast and write a business plan to help convince investors that your business idea can be profitable.

Choosing the right concept and positioning for your rubber and plastic manufacturing business

Once your market research is completed, it's time to consider the type of rubber and plastic manufacturing business you want to open and define precisely your company's market positioning in order to capitalise on the opportunity you identified during your market research.

Market positioning refers to the place your product and service offering occupies in customers' minds and how they differ from competing products and services. Being perceived as the premium solution, for example.

There are four questions you need to consider:

- How will you compete with and differentiate yourself from competitors already on the market?

- Is it better to start or buy a rubber and plastic manufacturing business already in operation?

- How will you validate your concept and market positioning?

Let's look at each of these in a little more detail.

How will you compete with and differentiate yourself from competitors already on the market?

When you choose to start up a rubber and plastic manufacturing business, you are at a disadvantage compared to your rivals who have an established presence on the market.

Your competitors have a reputation, a loyal customer base and a solid team already in place, whereas you're starting from scratch...

Entering the market and taking market share from your competitors won't happen automatically, so it's important to carefully consider how you plan to establish your presence.

There are four questions to consider here:

- Can you avoid direct competition by targeting a customer segment that is currently poorly served by other players in the market?

- Can you offer something unique or complementary to what is already available on the market?

- How will you build a sustainable competitive advantage for your rubber and plastic manufacturing business?

- Do you have the resources to compete with well-established competitors on your own, or would it be wiser to explore alternative options?

Also, think about how your competitors will react to your arrival in their market.

Is it better to start or buy a rubber and plastic manufacturing business already in operation?

An alternative to opening a new business is to take over a rubber and plastic manufacturing business already trading.

Purchasing an existing rubber and plastic manufacturing business means you get a loyal customer base and an efficient team. It also avoids disrupting the equilibrium in the market by introducing a new player.

A takeover hugely reduces the risk of the business failing compared to starting a new business, whilst giving you the freedom to change the market positioning of the business taken over if you wish.

This makes buying an existing rubber and plastic manufacturing business a solid alternative to opening your own.

However, buying a business requires more capital compared to starting a rubber and plastic manufacturing business from scratch, as you will need to purchase the business from its current owner.

How will you validate your concept and market positioning?

Regardless of how you choose to establish your business, it's crucial to make sure that the way you position your company aligns with the expectations of your target market.

To achieve this, you'll have to meet with your potential customers to showcase your products or services and get their feedback.

Where should I base my rubber and plastic manufacturing business?

The next step in our guide on starting a rubber and plastic manufacturing business involves making a key choice about where you want your business to be located.

Picking the ideal location for your business is like selecting the perfect canvas for a painting. Without it, your business might not showcase its true colors.

We recommend that you take the following factors into account when making your decision:

- Parking space, road and public transport accessibility - A rubber and plastic manufacturing business requires frequent transportation of raw materials and finished products, so having easy access to roads and public transport is crucial for efficient logistics and cost-effective operations.

- Availability of skilled labor - This type of business requires specialized skills and knowledge in manufacturing processes and machinery. Being located in an area with a pool of skilled labor can help reduce training costs and ensure a high-quality workforce.

- Proximity to target customers - Being close to the target market can save on transportation costs and make it easier to build relationships with customers. For a rubber and plastic manufacturing business, this could mean being located near industries that use these materials, such as automotive or construction.

- Competitor presence - While competition can be a challenge, being located near competitors can also be an advantage. It can help attract customers who may be looking for alternative suppliers and also provide opportunities for collaboration or partnerships.

This list is not comprehensive and will have to be adjusted based on the details of your project.

The parameters to be taken into account will also depend on whether you opt to rent premises or buy them. If you are a tenant, you will need to consider the conditions attached to the lease: duration, rent increase, renewal conditions, etc.

Lease agreements differ widely from country to country, so it's essential to review the terms that apply to your situation. Before putting pen to paper, consider having your lawyer look carefully at the lease.

Need inspiration for your business plan?

Avoid writer's block and draft your own business plan in no time by drawing inspiration from dozens of business plan templates.

What legal form should I choose for my rubber and plastic manufacturing business?

The next step to start a rubber and plastic manufacturing business is to choose the legal form of your business.

The legal form of a business simply means the legal structure it operates under. This structure outlines how the business is set up and defines its legal obligations and responsibilities.

Why is your rubber and plastic manufacturing business's legal form important?

Choosing the right legal form for your rubber and plastic manufacturing business is important because this will affect:

- Taxation: your tax obligations depend on the legal structure you choose, and this principle applies to both personal income tax and business taxes.

- Risk exposure: some legal structures have a legal personality (also known as corporate personality) and limited liability, which separates them from the owners running the business. This means that the business would be liable rather than the owners if things were to go wrong (lawsuit, debt owed in case of bankruptcy, etc.).

- Decision-making and governance: how you make key decisions varies based on the legal form of your business. In some cases you might need to have a board of directors and organise general assemblies to enable shareholders to influence major decisions with their voting rights.

- Financing: securing funding from investors requires you to have a company and they will expect limited liability and corporate personality to protect them legally.

- Paperwork and legal formalities: the legal structure you select determines whether certain obligations are necessary, such as producing annual accounts, or getting your books audited.

Popular business legal forms

The specific names of legal structures vary from country to country, but they usually fall within the two main categories below:

- Individual businesses

- Companies

Individual businesses

Individual businesses, like sole traders or sole proprietorships, are made for self-employed entrepreneurs and freelancers rather than businesses which employ staff.

They benefit from straightforward administrative requirements, minimal paperwork to start, simpler tax calculations, and streamlined accounting procedures.

However, the downside is that there's typically no legal distinction between the business and the person responsible for day-to-day operations. This means the owner's personal assets are at risk if the business faces problems or goes bankrupt.

There is also no share capital in such a structure, meaning that individual businesses cannot raise equity from investors which seriously limits funding options.

Companies

Companies are versatile structures suited to projects of all sizes in terms of number of founders, number of employees and amount of capital.

They are a bit more complex to operate than individual businesses with more formalities, stringent accounting requirements, more complex tax implications, etc.

In return, they offer stronger protections to their shareholders. They usually benefit from having their own legal identity and limited liability, meaning co-founders and investors can only ever lose the amount of money they have put into the company.

For instance, if things were to go south (the company files for bankruptcy or there is a legal issue), the company would take the hit, safeguarding the personal assets of the founders and investors.

How should I choose my rubber and plastic manufacturing business's legal structure?

Deciding on a legal form is easy once you've estimated your sales, decided whether or not you need employees and figured out the number of co-founders joining you.

It's essential to remember that a solid business idea will succeed no matter which legal structure you pick. Tax laws change regularly, so you can't rely on specific tax advantages tied to a particular structure when starting a business.

A proven approach is to look at what legal structures your top competitors are using, and go with the most common option as a working assumption. Once your idea is mature enough, and you're getting closer to officially registering your business, you can get advice from a lawyer and an accountant to confirm your choice.

Can I switch my rubber and plastic manufacturing business's legal structure if I get it wrong?

Yes, changing your legal structure later is possible, though it may involve selling the old entity to a new entity in some cases, which adds further expenses. If you want to save on such costs, it makes sense to pick the correct legal form for your business the first time around.

Can your business idea be profitable?

Just enter your data and let The Business Plan Shop crunch the numbers. We will tell if your business idea can generate profits and cash flows, and how much you need to get started.

How much money do I need to start a rubber and plastic manufacturing business?

To answer this key question, we first need to look at the resources you'll need to launch your rubber and plastic manufacturing business and keep it running on a daily basis. Let's take a look at what that entails.

Since each venture is distinct, providing an average budget for starting a rubber and plastic manufacturing business is impossible.

We strongly advise careful consideration when reading estimates on the web. It’s best to ask yourself the following questions:

- Is my project similar (location, concept, planned size, etc.)?

- Can I trust where this information is coming from?

- Is the data fresh or stale?

Your thinking behind the investments and human resources required to launch and operate the business will then enable you to cost each item and include them in your financial forecast (which we'll look at later in this guide).

Once complete, the forecast will give you a precise idea of the initial investment required and profitability potential for your business idea.

Startup costs and investments to start a rubber and plastic manufacturing business

Let's start with the investments. To set up a rubber and plastic manufacturing business, initial working capital and investments can include the following items:

- Machinery and Equipment: This includes the purchase of machines and tools necessary for the production of rubber and plastic products, such as extruders, injection molding machines, and mixing equipment.

- Facility Upgrades: As a rubber and plastic manufacturing business, you may need to invest in upgrading your facilities to meet safety standards or increase production capacity. This could include renovations, expansions, or the installation of new systems, such as ventilation or waste management.

- Raw Materials and Inventory: In order to produce your products, you will need to purchase raw materials, such as rubber and plastic resins, additives, and packaging materials. These expenses can fluctuate depending on demand and market prices.

- Research and Development: As technology and materials evolve, it is important for a rubber and plastic manufacturing business to continuously invest in research and development in order to stay competitive. This could include new product development, process improvements, or testing and analysis equipment.

- Transportation and Shipping: In order to deliver your products to customers, you may need to invest in transportation and shipping equipment, such as trucks, forklifts, and pallet jacks. This is especially important if you have a large volume of orders or if you are expanding your market reach.

Of course, you will need to adapt this list to your company's specific needs.

Staffing requirements to operate a rubber and plastic manufacturing business

You'll also need to think about the staff required to run the business on a day-to-day basis.

The human resources required will vary according to the size of your company.

Once again, this list is only indicative and will need to be adjusted according to the specifics of your rubber and plastic manufacturing business.

Operating expenses of a rubber and plastic manufacturing business

The final point to consider when analyzing the resources required is the question of operating costs.

Operating expenses for a rubber and plastic manufacturing business may include:

- Raw materials: This includes the cost of purchasing rubber and plastic materials to be used in the manufacturing process.

- Labor costs: This includes the salaries, wages, and benefits of your manufacturing staff.

- Utilities: This includes the cost of electricity, water, and other utilities needed to operate the manufacturing facility.

- Rent or mortgage: If you own your manufacturing facility, this would be your mortgage payment. If you rent, this would be your monthly rent payment.

- Equipment maintenance: This includes the cost of maintaining and repairing equipment used in the manufacturing process.

- Packaging materials: This includes the cost of purchasing packaging materials for your finished products.

- Transportation costs: This includes the cost of shipping raw materials and finished products to and from your manufacturing facility.

- Marketing and advertising: This includes the cost of promoting your rubber and plastic products to potential customers.

- Accounting and bookkeeping fees: You will need to hire an accountant or bookkeeper to help you manage your financial records and file taxes.

- Insurance: This includes the cost of insuring your manufacturing facility, equipment, and products against potential risks.

- Software licenses: You may need to purchase software licenses for programs used in the manufacturing process, such as design software or inventory management software.

- Banking fees: This includes the fees associated with maintaining a business bank account, such as transaction fees and wire transfer fees.

- Legal fees: You may need to hire a lawyer to help you with legal matters related to your business, such as trademarking your brand or drafting contracts.

- Employee training: This includes the cost of training your manufacturing staff to ensure they are knowledgeable and skilled in their roles.

- Office supplies: This includes the cost of purchasing necessary office supplies, such as paper, ink, and pens.

Here also, this list will need to be tailored to the specifics of your rubber and plastic manufacturing business but should be a good starting point for your budget.

Creating a sales & marketing plan for your rubber and plastic manufacturing business

The next step to start a rubber and plastic manufacturing business is to think about how you are going to attract and retain customers.

You need to ask yourself the following questions:

- What actions can be leveraged to attract as many customers as possible?

- How will you then retain customers?

- What resources do you need to allocate for each initiative (human and financial)?

- How many sales and what turnover can you expect to generate in return?

How you will attract and retain customers depends on your ambition, the size of your startup and the nature of your exact concept, but you could consider the following initiatives.

Your sales forecast may also be influenced by seasonality related to your business type, such as fluctuations during busy holiday periods, and your competitive environment.

Can your business idea be profitable?

Just enter your data and let The Business Plan Shop crunch the numbers. We will tell if your business idea can generate profits and cash flows, and how much you need to get started.

How do I build my rubber and plastic manufacturing business financial forecast?

Let's now look at the financial projections you will need to prepare in order to open a rubber and plastic manufacturing business.

What is a rubber and plastic manufacturing business's financial projection?

Your financial forecast will help you budget your project so that you can evaluate:

- Its expected sales and growth potential

- Its expected profitability, to ensure that the business will be viable

- Its cash generation and financing requirements

Making your financial forecast is the only way to determine the amount of initial financing required to create your rubber and plastic manufacturing business.

There are lots of business ideas out there, but very few of them are viable, and making a financial forecast is the only way to ensure that your project makes economic and financial sense.

Creating a rubber and plastic manufacturing business financial projection is an iterative process, as you'll need to refine your figures as your business idea matures.

You'll start with a first high-level version to decide whether or not to continue working on the project.

Then, as your project takes shape, your forecasts will become increasingly accurate. You'll also need to test different assumptions to ensure that your idea of starting a rubber and plastic manufacturing business holds up even if your trading environment deteriorates (lower sales than expected, difficulties in recruiting, sudden cost increases or equipment failure problems, for example).

Your financial forecast will be part of your overall business plan, which we'll look at in more detail later. Your financial partners will use your business plan to decide if they want to finance you.

Once you've launched your business, you can compare your actual accounting figures with your forecasts, to analyze where the discrepancies come from, and then update your forecasts to maintain visibility over your future cash flows.

Financial forecasts are, therefore, a financial management tool that will be with you throughout the life of your company.

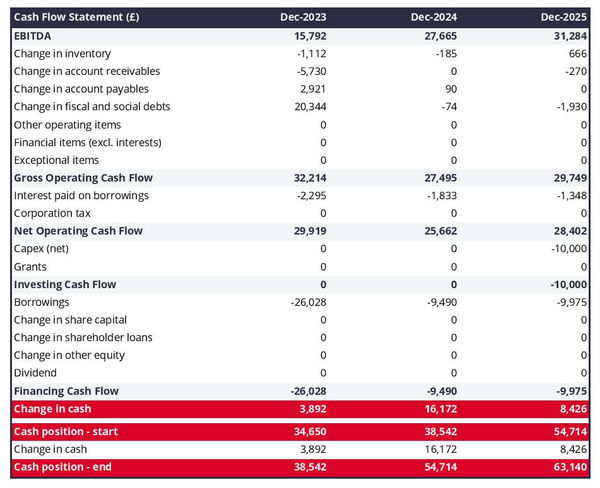

What does a financial projection look like?

Your rubber and plastic manufacturing business forecast will be presented using the following financial tables.

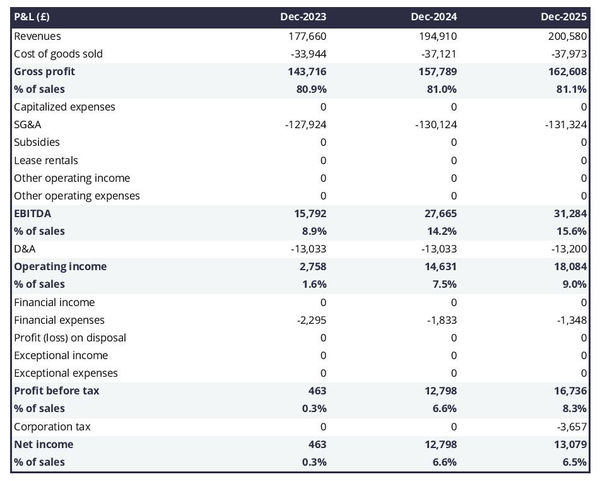

The projected P&L statement

The projected P&L statement for a rubber and plastic manufacturing business shows how much revenue and profits your business is expected to generate in the future.

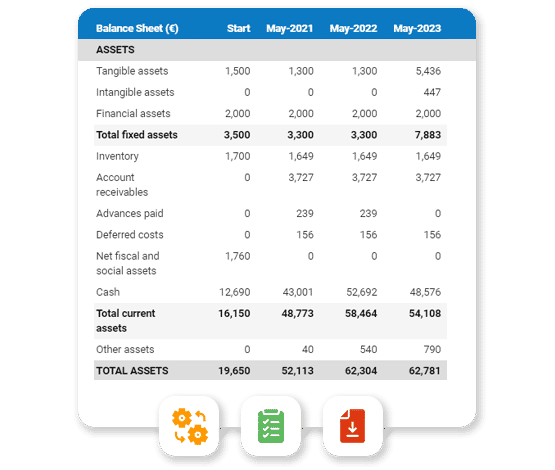

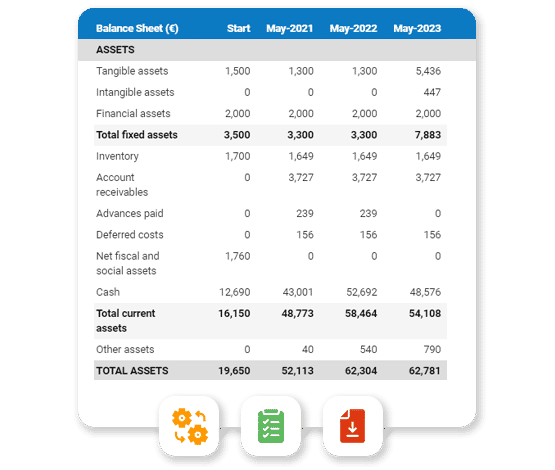

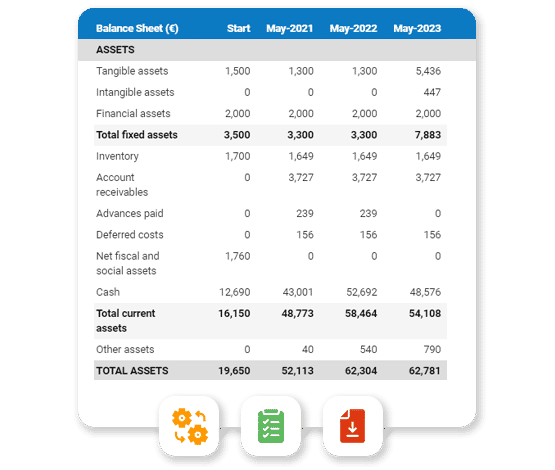

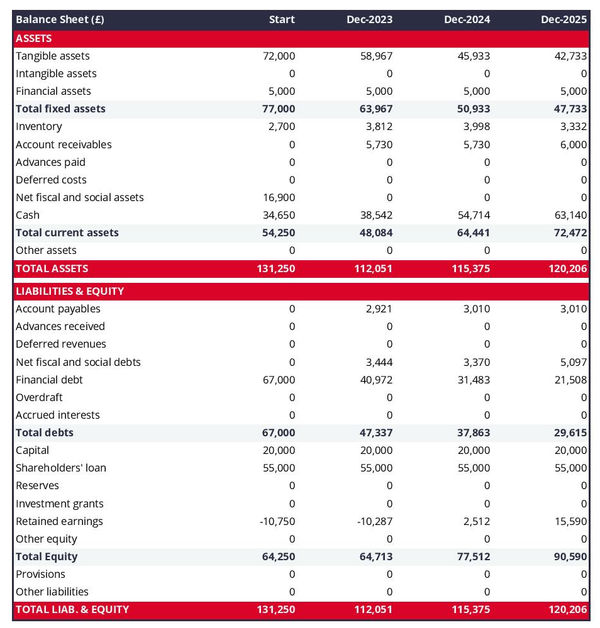

The projected balance sheet of your rubber and plastic manufacturing business

Your rubber and plastic manufacturing business's projected balance sheet provides a snapshot of your business’s financial position at year-end.

The cash flow forecast

A projected cash flow statement for a rubber and plastic manufacturing business is used to show how much cash the business is expected to consume or generate in the years to come.

Which solution should you use to make a financial forecast for your rubber and plastic manufacturing business?

The easiest and safest way to create your rubber and plastic manufacturing business forecasts is to use an online financial forecasting software, like the one we offer at The Business Plan Shop.

There are several advantages to using professional software:

- You can easily create your financial forecast by letting the software take care of the financial calculations for you without errors

- You have access to complete financial forecast templates

- You get a complete financial forecast ready to be sent to your bank or investors

- The software helps you identify and correct any inconsistencies in your figures

- You can create scenarios to stress-test your forecast's main assumptions to stress-test the robustness of your business model

- After you start trading, you can easily track your actual financial performance against your financial forecast, and recalibrate your forecast to maintain visibility on your future cash flows

- You have a friendly support team on standby to assist you when you are stuck

If you are interested in this type of solution, you can try our forecasting software for free by signing up here.

How do I choose a name and register my rubber and plastic manufacturing business?

Now that your project of launching a rubber and plastic manufacturing business is starting to take shape, it's time to look at the name of your business.

Finding the name itself is generally fairly easy. The difficulty lies in registering it.

To prevent this guide from being too long, we won't go into all the criteria you need to take into account when choosing a striking name for your rubber and plastic manufacturing business. However, try to choose a name that is short and distinctive.

Once you have a name that you like, you need to check that it is available, because you cannot use a name that is identical or similar to that of a competitor: this type of parasitic behaviour is an act of unfair competition for which you risk being taken to court by your competitors.

To avoid any problems, you will need to check the availability of the name:

- Your country's company register

- With the trademark register

- With a domain name reservation company such as GoDaddy

- On an Internet search engine

If the desired name is available, you can start the registration process.

It is common to want to use the trading name as the name of the company, and to have a domain name and a registered trademark that also correspond to this name: Example ® (trading name protected by a registered trademark), Example LTD (legal name of the company), example.com (domain name used by the company).

The problem is that each of these names has to be registered with a different entity, and each entity has its own deadlines:

- Registering a domain name is immediate

- Registering a trademark usually takes at least 3 months (if your application is accepted)

- The time taken to register a new business depends on the country, but it's generally quite fast

How do I go about it?

Well, you have two choices:

- Complete all registrations at the same time and cross your fingers for a smooth process.

- Make sure to secure the domain names and trademarks. Once that's done, wait for confirmation of a successful trademark registration before moving on to register the company.

At The Business Plan Shop, we believe it's essential to prioritize securing your domain names and trademarks over the business name. This is because you have the flexibility to use a different trading name than your legal business name if needed.

Regardless, we suggest discussing this matter with your lawyer (see below in this guide) before making any decisions.

Need inspiration for your business plan?

Avoid writer's block and draft your own business plan in no time by drawing inspiration from dozens of business plan templates.

Deciding upon the corporate identity of your rubber and plastic manufacturing business

The next step in opening a rubber and plastic manufacturing business is to look at your company's visual identity.

Your company's “visual identity” plays a crucial role in shaping your brand image. It helps you to be recognizable and to stand out from your competitors.

Although you can define your visual identity yourself, it is generally advisable to call on the services of a designer or marketing agency to achieve a professional result.

At a minimum, you will need to define the following elements:

- Logo

- Brand guidelines

- Business cards

- Website theme

Logo

Your rubber and plastic manufacturing business's logo allows others to quickly identify your company. It will be used on all your communication media (website, social networks, business cards, etc.) and official documents (invoices, contracts, etc.).

In addition to its design, it's important that your logo is available in a variety of colors, so that it can be seen on all media (white, dark background, etc.).

Brand guidelines

Having brand guidelines enables you to maintain consistency in formatting across all your communications media and official documents.

Brand guidelines define the font (family and size), design and colours used by your brand.

In terms of fonts, for example, you may use Roboto in size 20 for your titles and Lato in size 14 for your texts.

The colours used to represent your brand should generally be limited to five:

- The main colour,

- A secondary colour (the accent),

- A dark background colour (blue or black),

- A grey background colour (to vary from white),

- Possibly another secondary colour.

Business cards

Designing business cards for your rubber and plastic manufacturing business is a must, as they will allow you to communicate your contact details to your customers, suppliers, partners, potential recruits, etc.

In principle, they will include your logo and the brand guidelines that we mentioned above.

Website theme

In the same way, the theme of your rubber and plastic manufacturing business website will be based on your logo and the brand guidelines we mentioned above.

This involves defining the look and feel of your site's main graphic elements:

- Buttons,

- Menus,

- Forms,

- Banners,

- Etc.

Navigate the legal and regulatory requirements for launching your rubber and plastic manufacturing business

The next thing to do in getting a rubber and plastic manufacturing business off the ground is to handle all the legal and regulatory requirements. We recommend that you be accompanied by a law firm for all of the steps outlined below.

Intellectual property

One of your priorities will be to ensure that your company's intellectual property is adequately protected.

As explained before, you can choose to register a trademark. Your lawyer can help you with a detailed search to make sure your chosen trademark is unique and doesn't clash with existing ones.

They'll assist in preparing the required documents and steer you in picking the right categories and locations for trademark registration.

Moreover, your lawyer can offer guidance on additional measures to protect other intellectual property assets your company may have.

Getting your rubber and plastic manufacturing business paperwork in order

For day-to-day operations, your rubber and plastic manufacturing business will need to rely on a set of contractual documents.

Your exact needs in this respect will depend on the country in which you are launching your rubber and plastic manufacturing business, the number of partners and the envisaged size of the company.

However, you will probably need at least the following documents:

- Employment contracts

- General terms and conditions of sale

- General terms and conditions of use for your website

- Privacy Policy for your website

- Cookie Policy for your website

- Invoices

- Etc.

Applying for licences and permits and registering for various taxes

Operating your business legally may require licences and business permits. The exact requirements applicable to your situation will depend on the country in which you set up your rubber and plastic manufacturing business.

The lawyers who advise you will also be able to guide you with regard to all the rules applicable to your business.

Similarly, your accountant will be able to help you take the necessary steps to comply with the tax authorities.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast and write a business plan to help convince investors that your business idea can be profitable.

Create a business plan for your rubber and plastic manufacturing business

The next step to open a rubber and plastic manufacturing business: put together your business plan.

What is a business plan?

To keep it simple, a business plan comprises two crucial components:

- Firstly, a numerical part, the financial forecast (which we mentioned earlier), which highlights the initial financing requirements and profitability potential of the rubber and plastic manufacturing business,

- And a written, well-argued section that presents your project in detail, aims to convince the reader of its chances of success, and provides the context needed to assess whether the forecast is realistic or not.

The business plan will enable you to verify the coherence of your project, and ensure that the company can be profitable before incurring further costs. It will also help you convince business and financial partners.

As you can see, your business plan must be convincing and error-free.

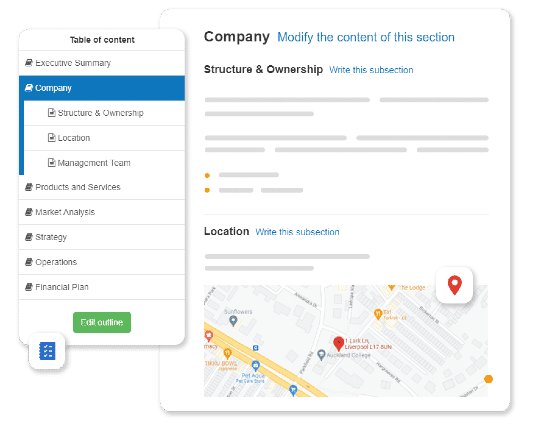

How to write a business plan for a rubber and plastic manufacturing business?

Nowadays, the modern and most efficient way to write a rubber and plastic manufacturer business plan is to use startup business plan software like the one we offer at The Business Plan Shop.

Using The Business Plan Shop to create a business plan for arubber and plastic manufacturing business has several advantages :

- You can easily create your financial forecast by letting the software take care of the financial calculations for you without errors

- You are guided through the writing process by detailed instructions and examples for each part of the plan

- You can access a library of dozens of complete startup business plan samples and templates for inspiration

- You get a professional business plan, formatted and ready to be sent to your bank or investors

- You can create scenarios to stress test your forecast's main assumptions

- You can easily track your actual financial performance against your financial forecast by importing accounting data

- You can easily update your forecast as time goes by to maintain visibility on future cash flows

- You have a friendly support team on standby to assist you when you are stuck

If you're interested in using this type of solution, you can try The Business Plan Shop for free by signing up here.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast and write a business plan to help convince investors that your business idea can be profitable.

Financing the launch of your rubber and plastic manufacturing business

Once your business plan has been written, you’ll need to think about how you might secure the funding required to open your rubber and plastic manufacturing business.

The amount of initial financing required will of course depend on the size of your rubber and plastic manufacturing business and the country in which you wish to set up.

Financing your startup will probably require you to obtain a combination of equity and debt, which are the primary financial resources available to businesses.

Equity funding

Equity refers to the amount of money invested in your rubber and plastic manufacturing business by founders and investors and is key to starting a business.

Equity provides your company with stable, long-term (often permanent) capital. It also demonstrates the commitment of the company's owners to the project, since these sums can be lost in the event of bankruptcy.

Because the equity invested by the founders may be lost if the project doesn't succeed, it signals to investors and other financial institutions the founders' strong belief in the business's chances of success and might improve the likelihood of obtaining further funding as a result.

In terms of return on investment, equity investors receive dividends paid by the company (provided it is profitable) or realise capital gains by reselling their shares (provided they find a buyer interested in the company).

Equity investors are, therefore, in a very risky position. They stand to lose their initial investment in the case of bankruptcy and will only obtain a return on investment if the business manages to be profitable or sold. On the other hand, they could generate a very high return if the venture is a financial success.

Given their position, equity investors are usually looking to invest in business ventures with sufficient growth and profitability potential to offset their risk.

From the point of view of the company and its creditors, equity reduces risk, since equity providers finance the company and are only remunerated in the event of success.

From a technical standpoint, equity consists of:

- Share capital and premiums: which represent the amount invested by the shareholders. This capital is considered permanent as it is non-refundable. In return for their investment, shareholders receive shares that entitle them to information, decision-making power (voting in general assembly), and the potential to receive a portion of any dividends distributed by the company.

- Director loans: these are examples of non-permanent capital advanced to the company by the shareholders. This is a more flexible way of injecting some liquidity into your company than doing so as you can repay director loans at any time.

- Reserves: these represent the share of profits set aside to strengthen the company's equity. Allocating a percentage of your profits to the reserves can be mandatory in certain cases (legal or statutory requirement depending on the legal form of your company). Once allocated in reserves, these profits can no longer be distributed as dividends.

- Investment grants: these represent any non-refundable amounts received by the company to help it invest in long-term assets.

- Other equity: which includes the equity items which don't fit in the other categories. Mostly convertible or derivative instruments. For a small business, it is likely that you won't have any other equity items.

The main sources of equity are as follows:

- Personal contribution from the founders' savings.

- Private investors: business angels, friends and family.

- Crowdfunding campaigns to find investors or collect donations (usually in exchange for a gift).

- Government initiatives such as loans on favourable terms to help partners build up their start-up capital.

Debt funding

Another option for partially funding your rubber and plastic manufacturing business is to borrow.

By definition, debt works in the opposite way to equity:

- Debt needs to be repaid, whereas equity is permanent.

- Lenders get a contractually guaranteed return, whereas equity investors only generate a return if the company is a success.

When a company borrows money, it agrees to pay interest and repay the borrowed principal according to a pre-established schedule. Therefore, lenders make money regardless of whether the company is profitable and their main risk is if the company goes bankrupt.

To limit their risk, lenders are usually conservative and cautious in their approach. They only finance projects where they are confident that they will be repaid in full.

Companies borrow in two ways:

- Against their assets: this is the most common way of borrowing. The bank finances a percentage of the price of an asset (a vehicle or a building, for example) and takes the asset as collateral. If the company cannot repay, the bank seizes the asset and sells it to limit its losses.

- Against their future cash flows: the bank evaluates the company's financial forecast to estimate its borrowing capacity and assesses the conditions (amount, interest rate, term, etc.) on which it is prepared to lend, taking into account the credit risk posed by the company.

It's difficult to borrow against future cash flow when setting up a rubber and plastic manufacturing business, because the business doesn't yet have historical data to reassure lenders about the credibility of the forecasted cash flows.

Borrowing against assets is, therefore, often the only option available to entrepreneurs. What's more, the assets that can be financed with this option must be easy to resell, in the unfortunate event that the bank is forced to seize them, which may limit your options even further.

In terms of possible sources of borrowing, the main sources here are banks and credit institutions. Bear in mind, however, that each institution is different, both in terms of the risk it is prepared to accept and in terms of how the risk of your project will be perceived and what items it will agree to finance.

In some countries, it is also possible to borrow from private investors (directly or via crowdlending platforms) or other companies, but not everywhere.

Things to remember about financing a rubber and plastic manufacturing business

There are various ways you can raise the initial financing you need to open your rubber and plastic manufacturing business. A minimum amount of equity will be needed to give the project credibility, and bank financing can be sought to complete the package.

What to do after launching my rubber and plastic manufacturing business?

Launching your rubber and plastic manufacturing business is the beginning of an exciting entrepreneurial adventure, and the culmination of your efforts to turn your idea into a reality. But this is also when the real work begins.

As you know, nearly half of all new businesses fail, so you'll need to do everything you can to make your business sustainable right from the start.

Estimating the future financial performance of a rubber and plastic manufacturing business inevitably involves a degree of uncertainty. That's why we recommend simulating several scenarios: a central case with the most likely scenario, an optimistic case, and a pessimistic case designed to test the limits of your business model.

Normally, your company's actual financial performance, observed after you start trading, should fall somewhere between your pessimistic and optimistic cases.

The important thing will be to quickly measure and compare this actual performance with the figures in your forecast to see where you stand, then update the forecast to re-estimate the future cash flows and cash position of your rubber and plastic manufacturing business.

This forward-looking financial management exercise is the only way to know where you stand and where you're going. And, when your figures fall short of expectations, to quickly implement actions to turn things around before the company runs out of cash.

There's nothing more dangerous than waiting until you have your accounts, which takes up to nine months after the end of your financial year (if you are in the UK, abroad your mileage will vary), to then realize that you're not on the right track and that your rubber and plastic manufacturing business won't have enough cash to operate over the next twelve months.

This is where using a forecasting solution that integrates actuals vs. forecast tracking, like The Business Plan Shop's financial dashboards do, can simplify the financial management of your business and help reduce the risk associated with your start-up project.

Need inspiration for your business plan?

Avoid writer's block and draft your own business plan in no time by drawing inspiration from dozens of business plan templates.

Key takeaways

- There are 15 key steps to opening a rubber and plastic manufacturing business.

- Your financial forecast will enable you to accurately assess your initial financing requirements and the potential profitability of your project.

- Your business plan will give your financial partners the context they need to be able to judge the consistency and relevance of your forecast before deciding whether or not to finance the creation of your rubber and plastic manufacturing business.

- Post-launch, it's essential to have an up-to-date forecast to maintain visibility of your business's future cash flows.

- Using a financial planning and analysis platform that integrates forecasts, business plans and actual performance monitoring, such as The Business Plan Shop, makes the process easier and reduces the risks involved in starting a business.

We hope this guide has helped you understand how to open a rubber and plastic manufacturing business. Please don't hesitate to contact us if you have any questions or want to share your experience as an entrepreneur.

Also on The Business Plan Shop

Know someone who wants to start a rubber and plastic manufacturing business? Share this guide with them!